Services

Star Aviation puts quality first and provides value-added solutions to reduce No Fault Found, increase MTBUR, and reduce repetitive maintenance costs associated with premature removals.

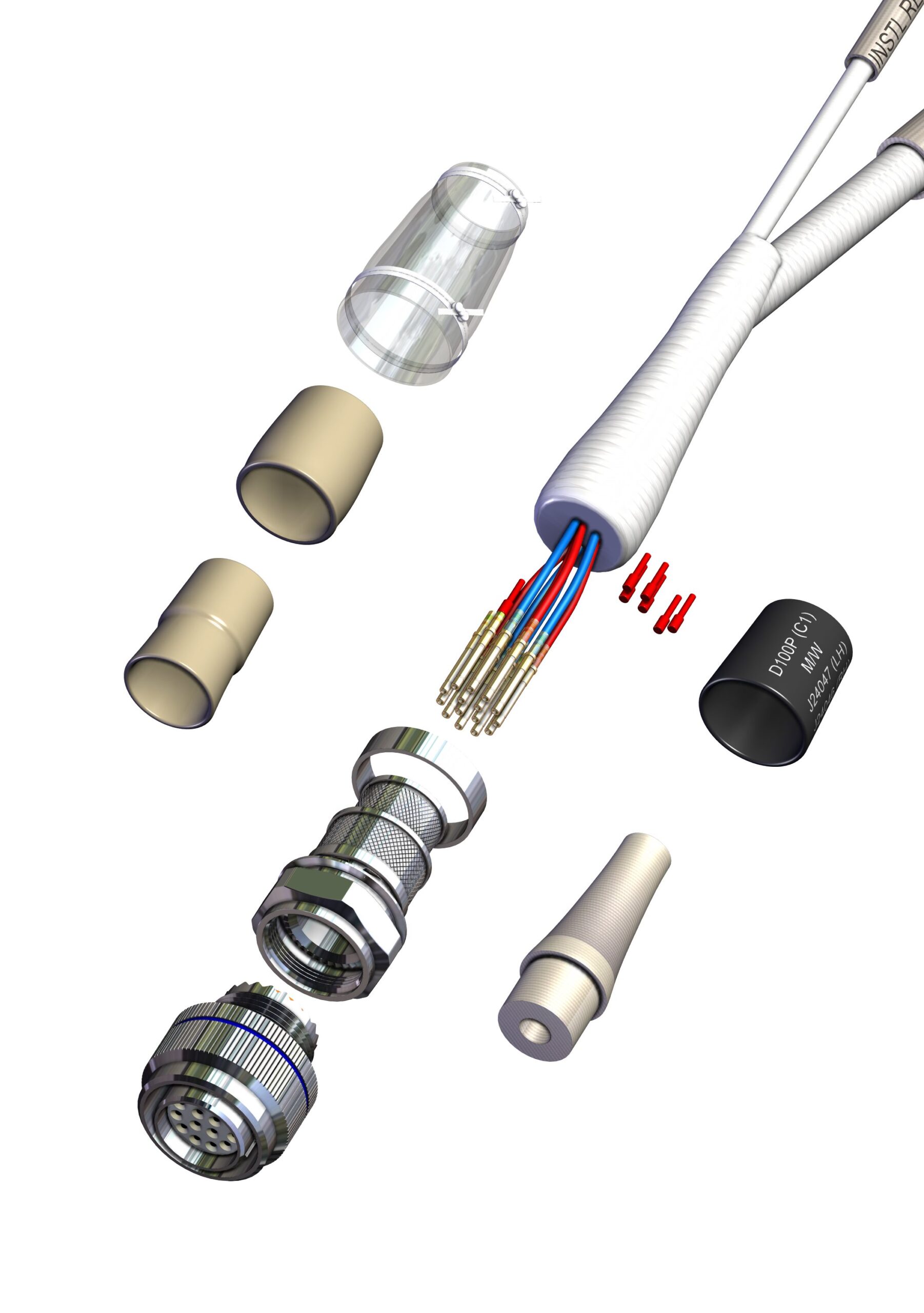

Wire Harness -Inspect/Test, Repair, Overhaul, and Modification

Star Aviation possesses extensive proficiency in the testing, repair, overhaul, and modification of wire harnesses utilized on Boeing and Airbus aircraft. Our array of cutting-edge equipment and tooling is pivotal in achieving precise fault isolation during evaluation, assembly, and testing, ensuring the utmost quality for the final product.

All hand tools are sourced from Daniels – DMC, guaranteeing the proper disassembly and assembly of each harness during the repair process, thus minimizing any potential damage. Furthermore, our computerized wire harness assembly boards play a vital role in enhancing assembly accuracy and maintaining process control throughout assembly. Additionally, the integrity of crimps for pins, contacts, terminals, and splices is meticulously examined under magnification to assess compression and ensure the inclusion of all wire strands within the crimp.

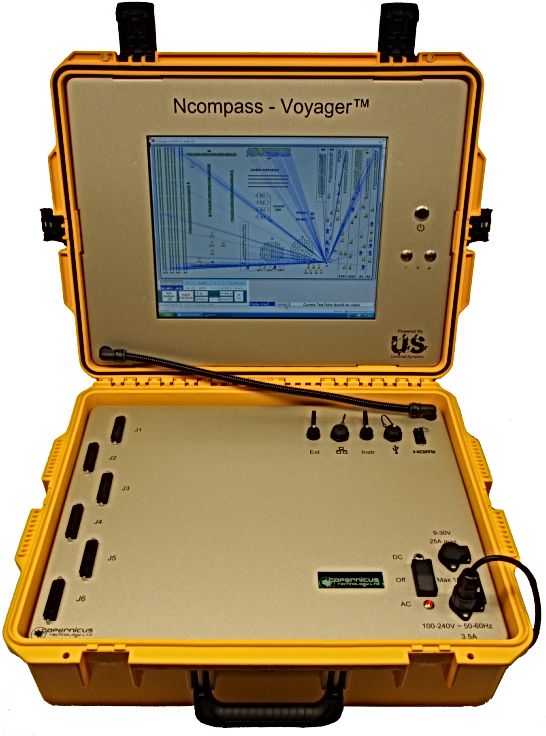

Intermittent Fault Detection System

Star Aviation stands out as the sole commercial provider offering Intermittent Fault Detection and Isolation System (IFDIS™) testing for LRUs, meeting the rigorous standards of MIL-PRF 32516. This system has been demonstrated as the singular effective solution for accurately detecting, isolating, and correction of intermittent faults in electronics.

IFDIS™ has been successfully employed by DOD Depot organizations for multiple years, yielding significant benefits. LRUs tested and repaired using IFDIS have experienced a remarkable minimum increase of 300% in Mean Time Between Unscheduled Removals (MTBUR), consequently reducing repetitive annual maintenance costs. Moreover, it has facilitated the recovery of assets previously deemed irreparable, resulting in substantial cost savings amounting to millions.

Our IFDIS™ test capability encompasses up to 5120 circuits, with the potential for expansion to over 20,000 circuits. By enabling diagnostics on all circuits simultaneously, we ensure the timely capture of intermittent faults as they manifest.

Customers seeking to elevate their testing and fault isolation capabilities can access our Portable Intermittent Fault Detection (PIFD) system. Designed for versatility, this portable solution empowers users to perform comprehensive tests, pinpointing and interpreting failures with precision. Its portable nature allows for testing to be conducted anywhere, ensuring flexibility and convenience for diagnostic procedures.

Wire Harnesses - Sales & Exchange

Alongside our top-tier wire harness repair services, we present our own inventory of overhauled wire harnesses available for sale or exchange. The majority of wire harnesses featured in our sales inventory are readily available on the shelf for immediate shipment. For those not currently overhauled, we ensure prompt readiness for shipment within 10 days or less.

Interface Test Adapter (ITA) Design and Manufacturing

Interface Test Assembly (ITA) systems serve as the interface through which a Unit Under Test (UUT) is connected to either the Intermittent Fault Detector (IFD™) or Intermittent Fault Detection and Isolation System (IFDIS™) to conduct intermittent fault diagnostics.

Tailored to meet individual customer needs, Star Aviation offers custom ITA solutions for wire harnesses or Line Replaceable Units (LRUs). This service is available for both commercial operators and military weapon systems, encompassing aircraft, missiles, ground vehicles, and more.

For inquiries regarding ITAs tailored to specific applications, please utilize the messaging option on our contact page or reach out to us directly at: +1 (502)-241-3072.

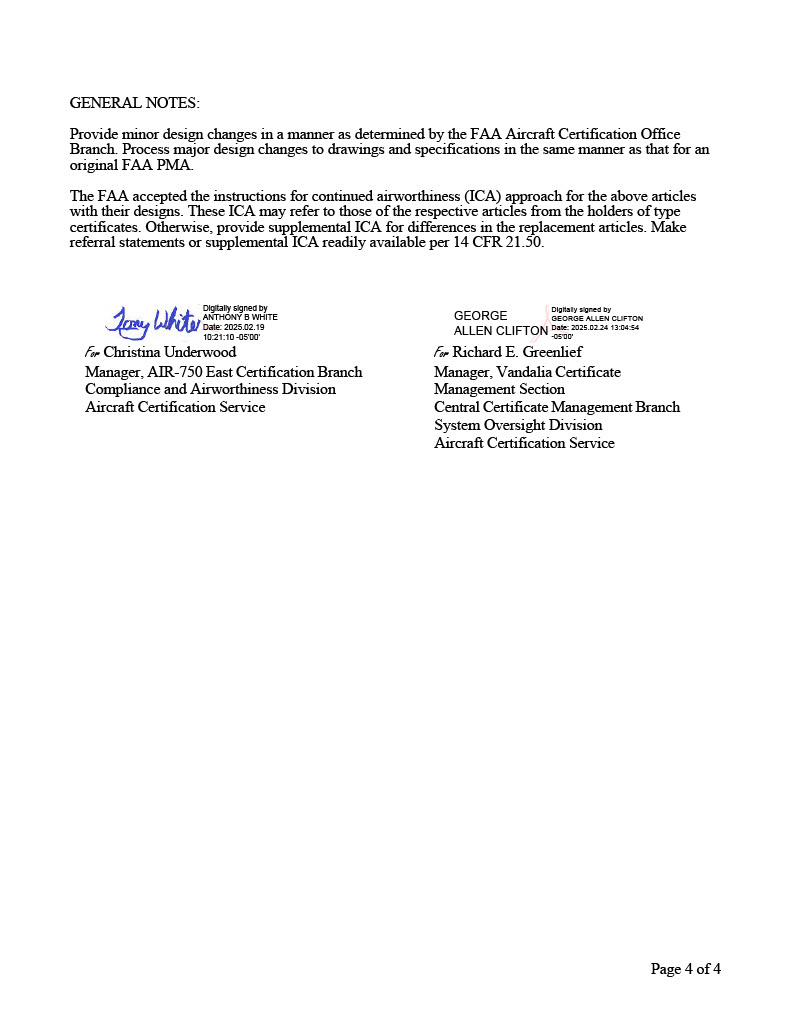

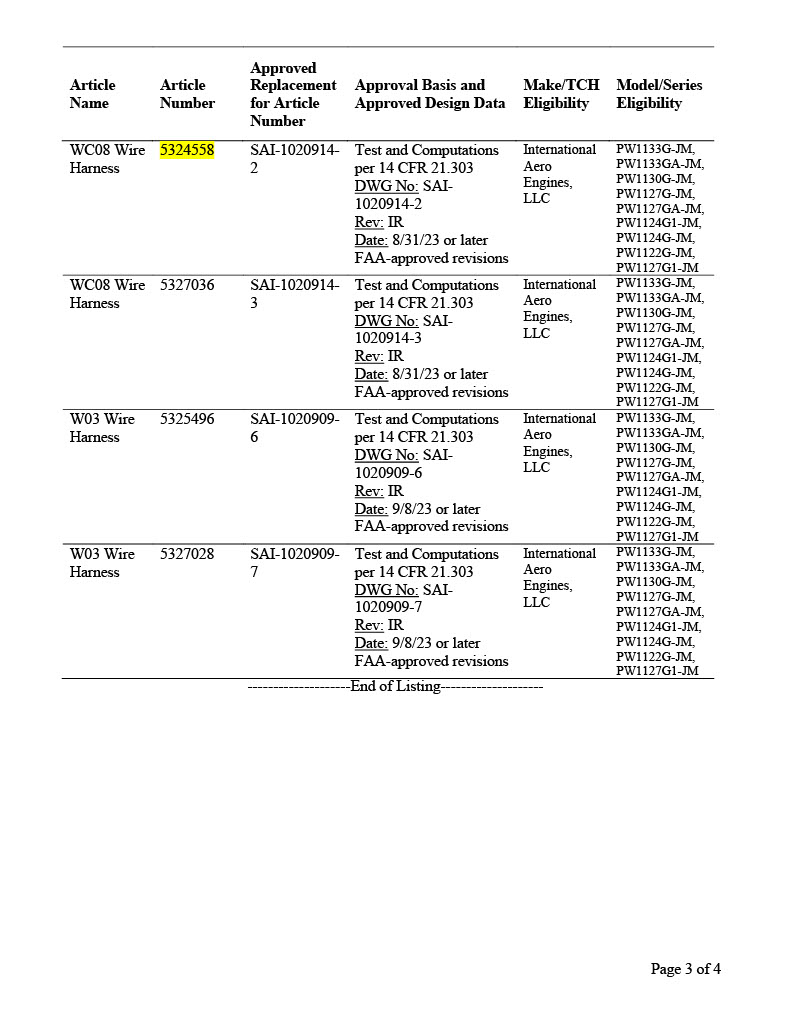

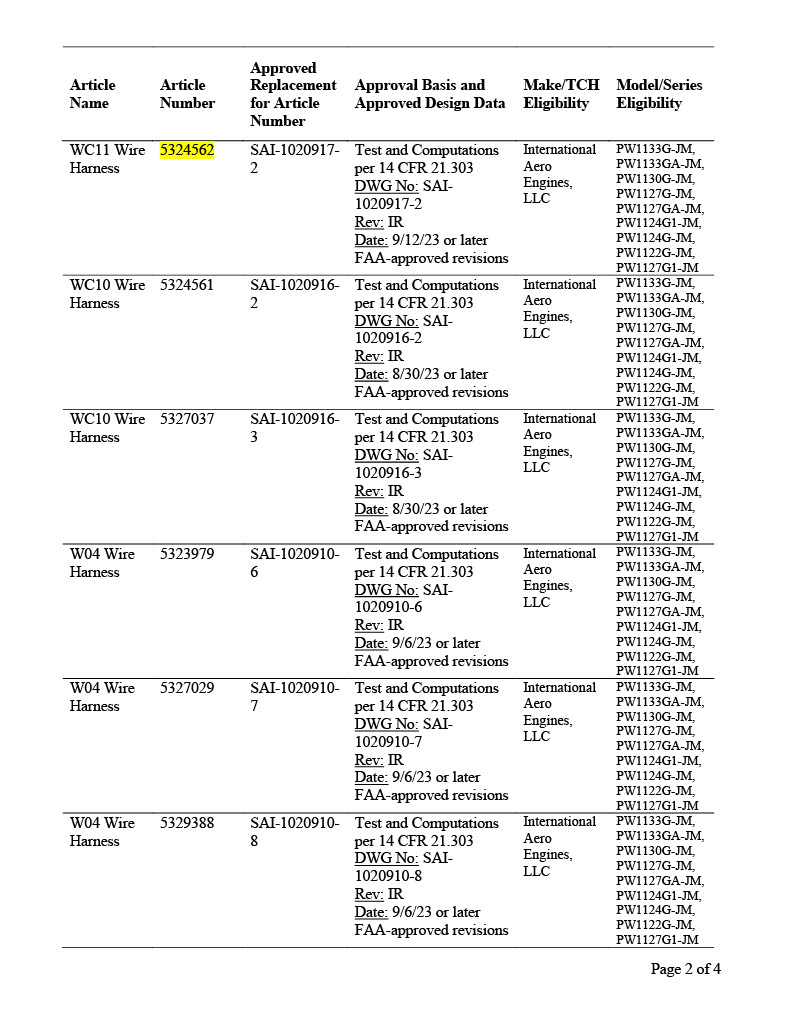

DER And PMA Capabilities

We take immense pride in our capabilities as a Designated Engineering Representative (DER) and Parts Manufacturer Approval (PMA) holder. With our DER authority, we possess the expertise and authorization to approve and oversee engineering designs, alterations, and repairs within the aviation industry. This designation underscores our commitment to ensuring that all engineering activities meet the stringent regulatory standards set forth by aviation authorities. Leveraging our DER capabilities, we offer a comprehensive range of services, including design modifications, structural analyses, and certification support, tailored to meet the unique needs of our clients.

Additionally, as a PMA holder, we have the authority to manufacture and certify aircraft parts, components, and systems in accordance with regulatory requirements. This designation enables us to develop innovative solutions that enhance aircraft performance, reliability, and safety while offering cost-effective alternatives to original equipment manufacturer (OEM) parts. Our PMA capabilities encompass the entire product lifecycle, from design and prototyping to manufacturing and certification, ensuring that our clients receive high-quality, FAA-approved parts that meet their specific requirements. With a steadfast commitment to excellence and regulatory compliance, we stand ready to deliver reliable, cutting-edge solutions through our DER and PMA capabilities.

Emergency Light Batteries

We have extensive experience testing and repairing emergency power supplies (P/N: 60-4411-5 and E650-03-001) ensuring their reliability and performance when it matters most. Our comprehensive capabilities cover all aspects of battery maintenance, from thorough testing to precise repairs.

With our state-of-the-art Cadex C8000 battery testing equipment and experienced technicians, we conduct detailed evaluations to assess the health and functionality of each battery. Our testing process is designed to identify any potential issues or weaknesses, allowing us to provide accurate recommendations for repair or replacement for the customer.

For batteries in need of repair, our skilled technicians utilize industry-leading practices to address any identified issues promptly and effectively. Whether it’s replacing internal batteries, repairing wiring connections, or replacing damaged circuit cards, we ensure that each battery is restored to optimal condition.

We understand the critical role that emergency power supplies play in aviation safety. That’s why we’re committed to delivering reliable, cost-effective solutions that our clients can trust. With our expertise in testing and repairing emergency power supplies, we help our clients maintain the highest levels of readiness and confidence in their aircraft systems.